Product

Home > Product > BROTHER > Single Needle

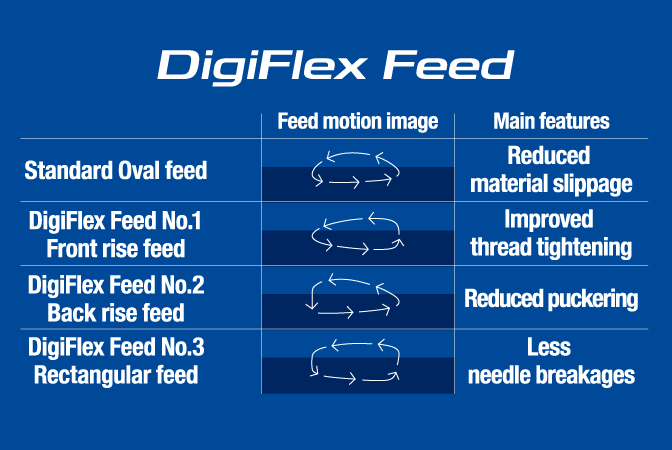

・Reduces needle breakage, puckering and materials slippage with DFF

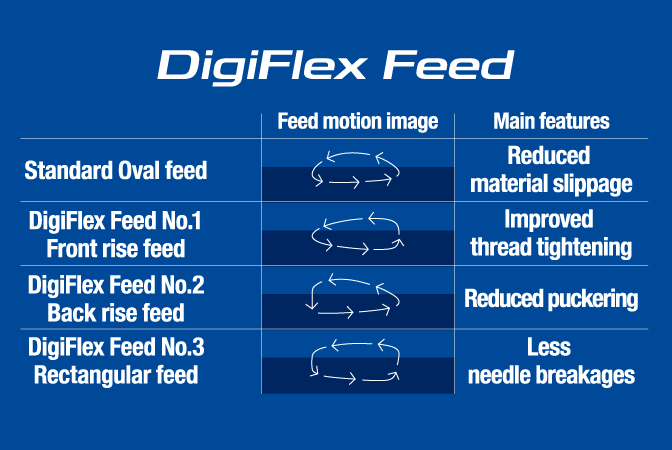

| DigiFlex Feed, which is world's first equipped on S-7300A and highly evaluated in the market, digitalizes feeding system and resolves various sewing troubles without adjustment work. |  |

| Fabric can be feed at an appropriate timing so that needle won't break even during thick material sewing. |  |

| Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage. |

| Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically. |

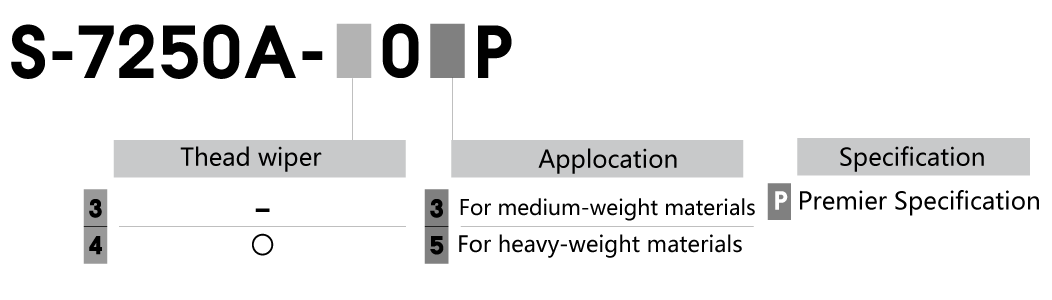

| S-7250A- | -303,-403 | -305,-405 | -303P, -403P | -303P, -403P |

| Lubrication type | Minimum lubrication | Minimum lubrication | ||

| Application | Medium materials | Heavy materials | Medium materials | Heavy materials |

| Max. sewing speed | 5,000 sti/min*1 | 4,000 sti/min | 5,000 sti/min*1 | 4,000 sti/min |

| Max. bac tacking speed | 3,000 sti/min | 3,000 sti/min | ||

| Max. stitch length | 5mm | Max.7mm(default setting:5mm) | 5mm | Max.7mm(default setting:5mm) |

| Thread trimming mechanism | Single action trimming mechanism (Ordinary type) | Double action trimming mechanism | ||

| Presser foot height | Presser bar lifter:6mm, Knee lifter: 13mm | Presser bar lifter:6mm, Knee lifter:13mm | ||

| Needle bar stroke | 31mm | 35mm |

31mm | 35mm |

| Needle (DBX1 ・DPX5) | #11-#18 (Nm75-110) |

#19-#22 (Nm120-140) |

#11-#18 (Nm75-110) |

#19-#22 (Nm120-140) |

| Height of feed dog | 0.8mm | 1.2mm | 0.8mm | 1.2mm |

| Weight | 35kg | 35kg | ||

| Motor | AC servo motor | AC servo motor | ||

| Power | 100-110V(*2),200V-230V,380V-400V(*2)under450VA | |||

*1 Stitch length 2.0mm and under

*2 The transformer is required.

World’s first Electronic Feed Control directory connected with stepping motor

DigiFlex Feed, which is world's first equipped on S-7300A and highly evaluated in the market,digitalizes feeding system and resolves various sewing troubles without adjustment work.

- Improvement in the reduction of needle breakage and productivity.

- Simple select and smooth sewing without material slippage.

- Excellent sewing quality that's easy to get proper thread tension in accordance with several materials

Needle Breakage Prevention with Brother Own 3 Functions

Optimization of fabric feed timing by changing feed motion of DFF

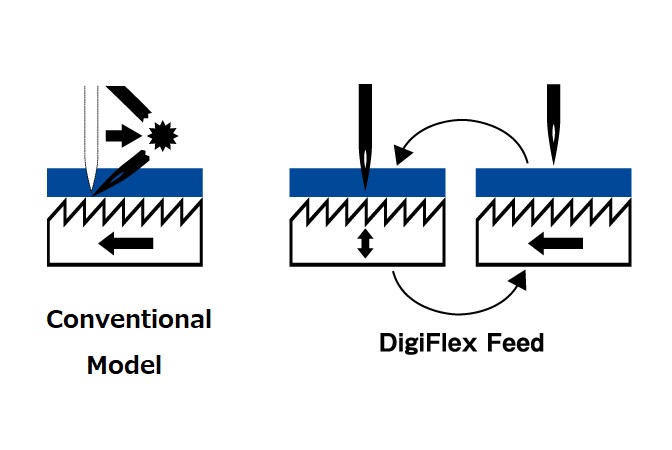

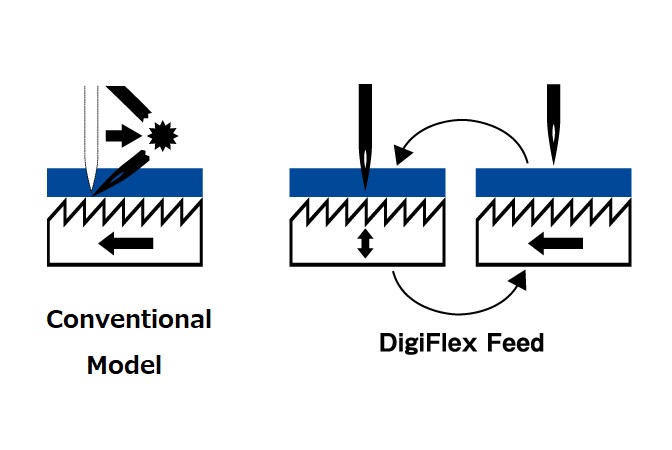

Fabric can be feed at an appropriate timing so that needle won't break even during thick material sewing.

Change from mechanical control to stepping motor control by equipped DFF

Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage.

Equipped with needle prevent breakage function while reverse sewing

Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically.

A Variety of Functions Realize Ease of Use and Ideal Sewing Quality

Beautiful stitching without puckering

OFF realizes appropriate thread tightening in relation with the fabric and reduces puckering.

Short remaining thread, (3mm) doesn't require after-cutting process

The new double action thread trimming mechanism cut's the thread right under the needle hole, realizing the short remaining thread at minimum of 3mm. The disposition of thread ends after sewing can be reduced thanks to the new system. (Premier Spec.)

Oil staining prevention

The closed oil tank enables clean sewing more than conventional model's that does stain sewing material. The minimum lubrication system prevents problems such as oil leakage and oil scattering drastically.

Easy operation with a simple panel

You can change the stitch length and sewing speed easily. In addition, it is possible to set the stitch length as a numerical value, and the reproducibility of sewing is improved.

Stress relief at reverse sewing

Because the reverse sewing is changed to motor control, vibration and noise are suppressed. It contributes a stress relief.

Reduction of hanging fabric

By arranging rubber on the back side which had been installed at the four comers of the bed of the sewing machine on the surface, it becomes easier to handle the fabric.

Productivity Improvement by Improving Production Management with loT

Productivity improvement with loT

NEXIO series are loT applicable models. The visualization by connecting sewing machine and computer technology enables the customer to analyze, manage processes and speed up productivity improvement and maintenance work.

Easy management and secure with data USB

Data transfer to other sewing machines and software upgrade can be done with USB memory easily.