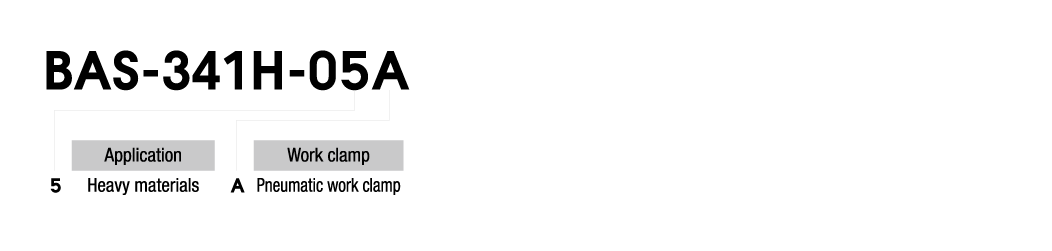

Product

Home > Product > BROTHER > Programmable Electronic Pattern

Description

・World’s Top-class Sewing Speed of 2,800sti/min with High Quality Sewing

| Higher rigid feed mechanism was adopted while achieving the world’s top-class sewing speed of 2,800sti/min. With its accurate stitch point, the machine can perform beautiful stitching with stable thread tightening. |  |

| Powerful motor(550W) outputs large amounts of torque even at slow speeds so that strong needle penetration force can be obtained. If the needle penetration resistance increases, vibration control(intermittent impact) automatically increases the penetration force. |  |

| The upper thread tension can be digitalized with the Digital Tension, providing stable stitching. No more relying on individual feel. When thread breakage is detected, sewing operation is stopped automatically and a warning is given to the operator, leading to the less detectives. |  |

| 7-inch large screen and easy programming functions via LCD touch panel enable an intuitive operation. It is easily understood without the instruction manual or previous experience in fewer steps. |  |

| BAS-341H | |

| Stitch form | Single needle lock stitch |

| Max. sewing speed | 2,800sti/min*1 |

| Max. sewing area | 250.0x160.0mm |

| Feed mechanism | Intermittent feed (pulse motor drive) |

| Stitch length | 0.05-12.7mm (per 0.05mm) |

| Max. number of stitches | 20,000 stitches (per program) |

| Max. number of programs | 999 |

| Work clamp drive | Pneumatic drive |

| Work clamp lift amount | Max. 30.0mm |

| 2-step work clamp | Integrated-type |

| Height of steppong presser foot | 22.0mm |

| Stepping presser foot stroke | 2.0mm-4.5mm、4.5mm-10mm or 0mm (Default setting: 3.0mm) |

| Hook | Double-capacity shuttle hook |

| Thread wiper | ◯ |

| Thread trimmer | ◯ |

| Digital tension | ◯ (excluding the seat belt specification) |

| Thread breakage detector | ◯ |

| Data strage media | Internal flash memory (data addition is available with external memory) |

| Motor | AC servo motor 550W |

| Weight | Machine head: 166kg Control box: 18kg |

| Power | Single phase: 220V 3-phase: 200V/220V/380V/400V |

| Air pressure/ Consumption | 0.5MPa 1.8l/min |

|

|

Lineusps for your various types of sewing applications

We have 5 lineups as BAS-H series with different sewing area. You can select the best model for your applications sucu as label, airbags, seat belts and so on.

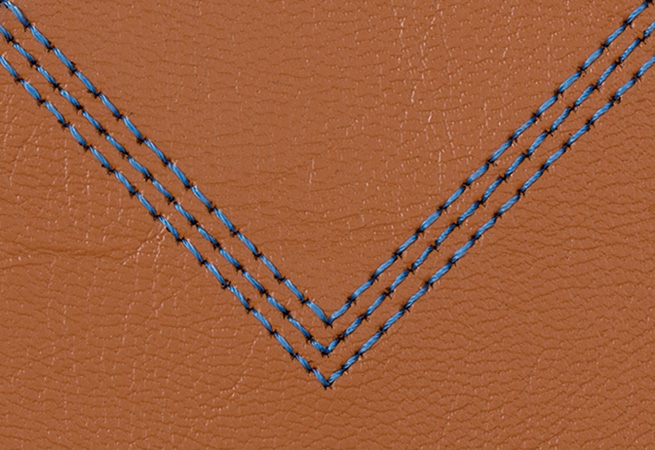

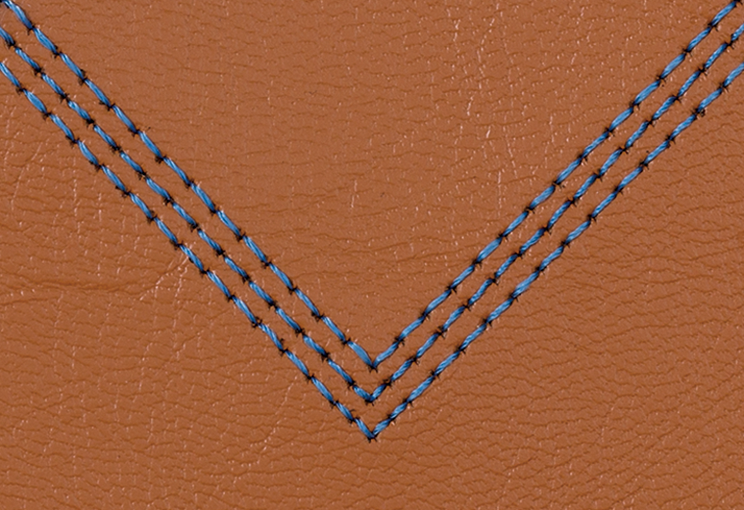

World's top-class sewing speed of 2,800sti/min with high quality sewing

Higher rigid feed mechanism was adopted while achieving the world's top-class sewing speed of 2,800 sti/min. With its accurate stitch point, the machine can perform beautiful stitching with stable thread tightening.

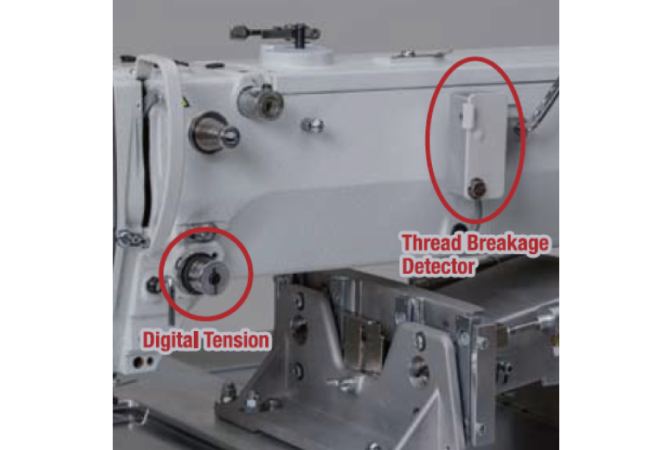

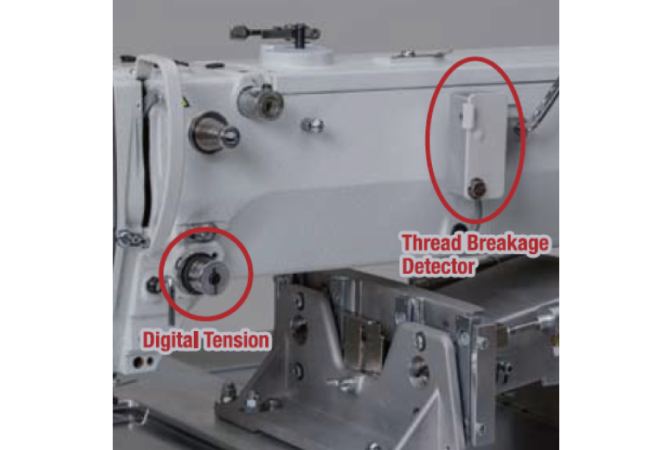

Digital tension and thread breakage detector as standard equipment

The upper thread tension can be digitalized with the Digital Tension, providing stable stitching. No more relying on individual feel. When thread breakage is detected, sewing operation is stopped automatically and warning is given to the operator, leading to the less detectives.

Great Needle Penetration

Powerful motor(550W) outputs large amounts of torque even at slow speeds so that strong needle penetration force can be obtained. If the needle penetration resistance increases, vibration control(intermittent impact) automatically increases the penetration force.

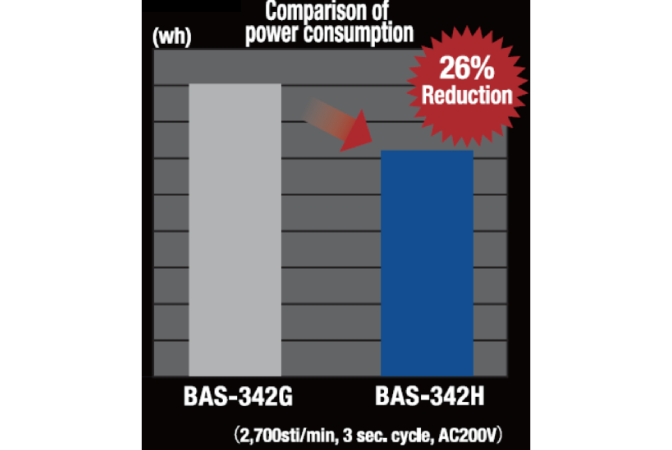

High Energy Saving

This machine is the most energy-saving programmable electronic pattern sewing machine among in its class, while realizing high-speed sewing and strong needle penetration force.

Uniform and Stable Thread Tightness

It realized stable thread tightening at low tension sewing. Excessive or insufficient pressing by the stepping foot can be prevented, enabling a finish with uniform thread tightening.

Easy and Accurate Positioning of Materials

You can select a desired work clamp lowering operation from two patterns by changing the memory switch settings (Two-step lowering or One-step lowering). (BAS-341H/342H only)

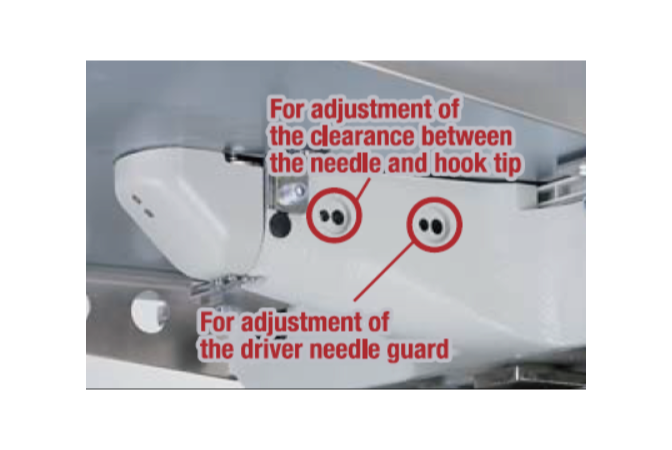

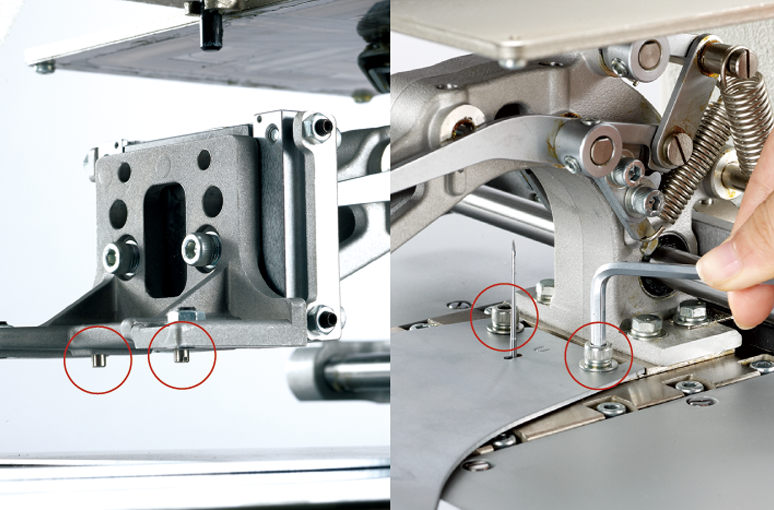

Simple Adjustment

The driver can be adjusted from the side without tilting the sewing machine. This reduces time taken for adjustment and improves productivity when materials are changed.

Simple and Easy Sewing Pattern Change

The work clamp can be replaced quickly by loosening the two screws (BAS-311HN/326H), and four screws (BAS-341H/342H). When replacing the feed plate, align the reference holes of needle plate and the feed plate.

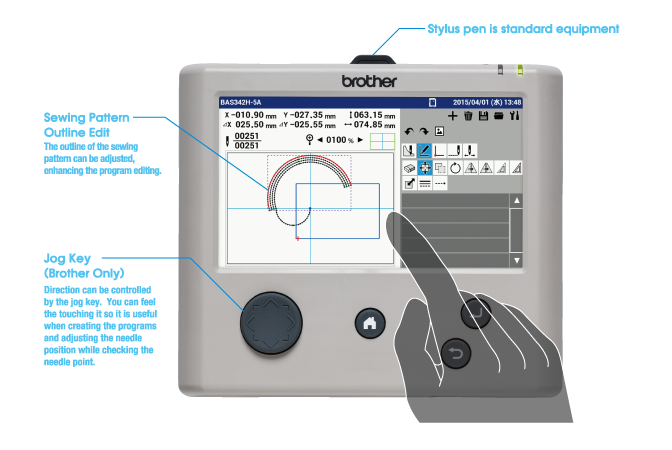

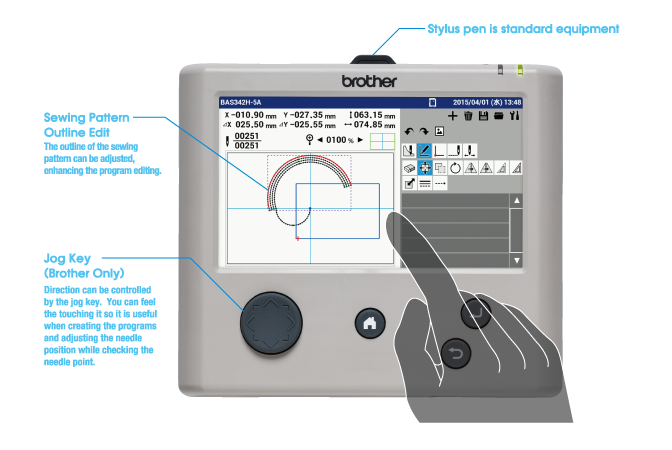

Best User Experience with LCD Touch Panel

7-inch large screen and easy programming functions via LCD touch panel enable an intuitive operation. It is easily understood without the instruction manual or previous experience in fewer steps.

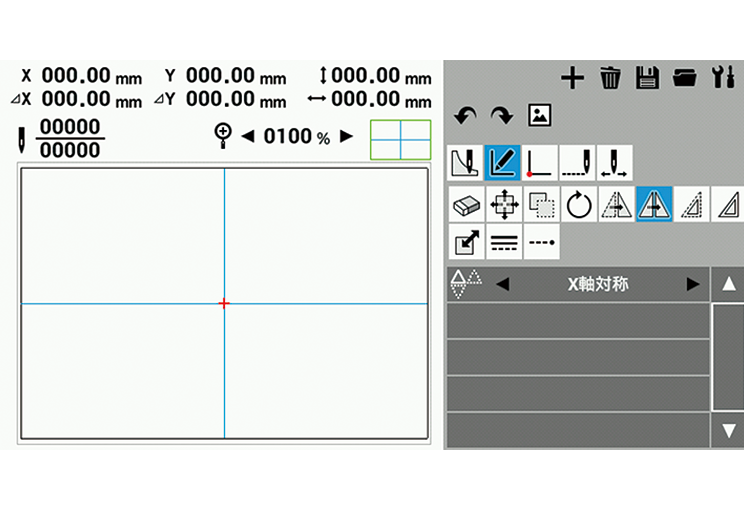

Program Creating

Program creation can be available easily with illustration icons.

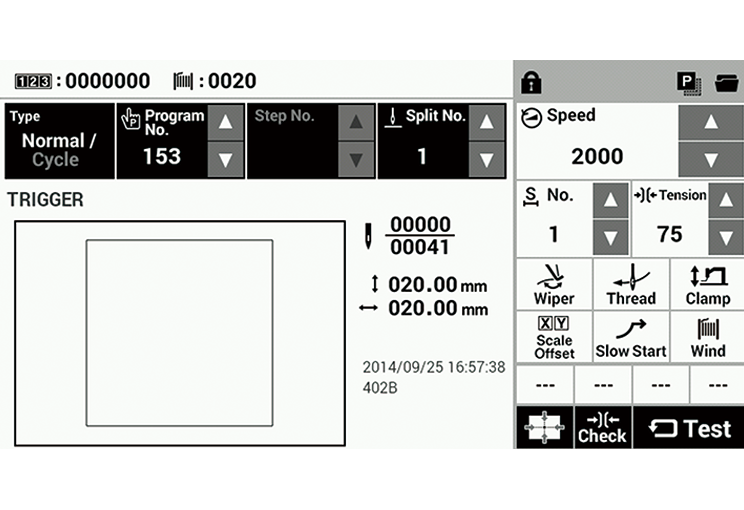

Program Selection

The information regarding the program is seen at one screen. The setting change is available on it.

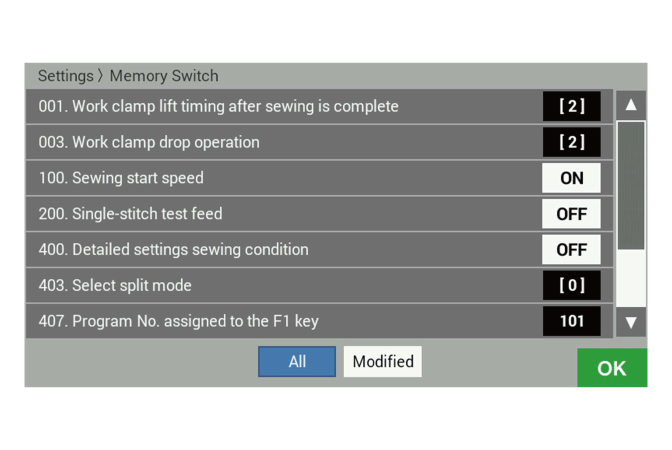

Memory Switch Settings

The detail of Memory switch settings can be checked on the panel without the manuals.

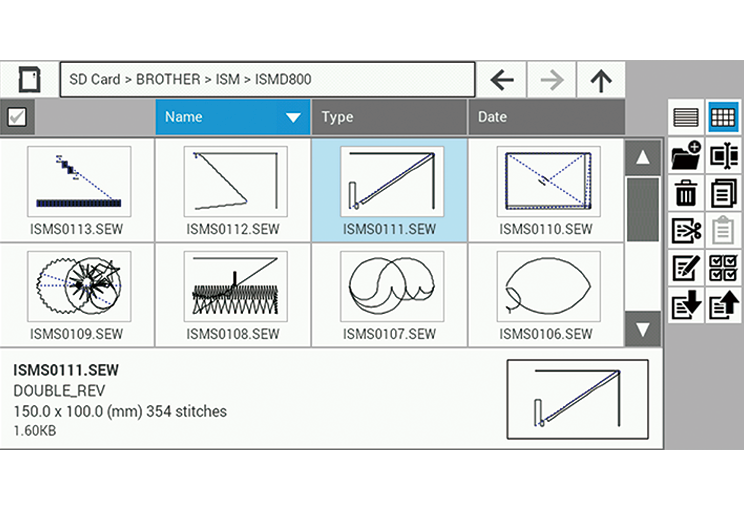

File Selection

The preview of the program can be seen on the panel.

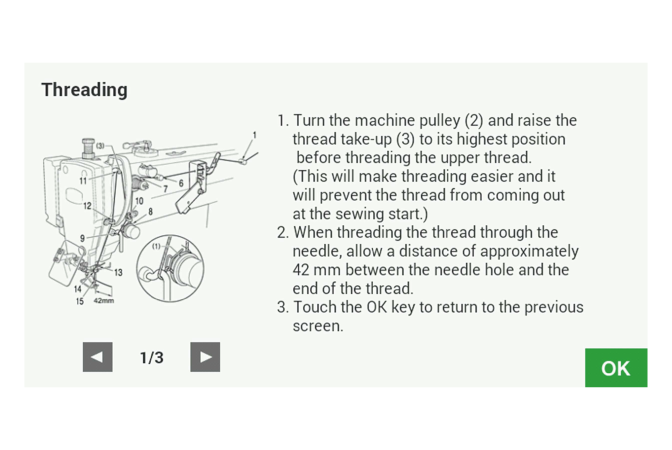

Manual Display

The mistakable preparations such as Threading the upper thread, Winding the lower thread can be checked on the panel.

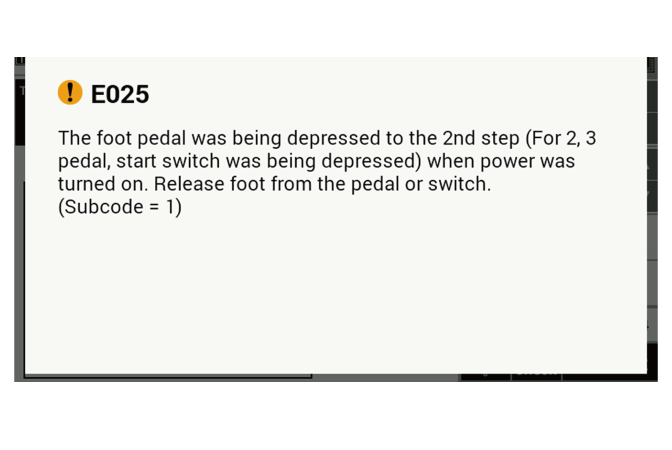

Error Message Display

When an error occurs, the error message and solution are displayed on the panel, helping reduce the downtime.

Multimedia Support

Supporting the SD card (1 slot), USB (2 port). An expansion port is also supported, enabling to connect with a bar code reader etc.

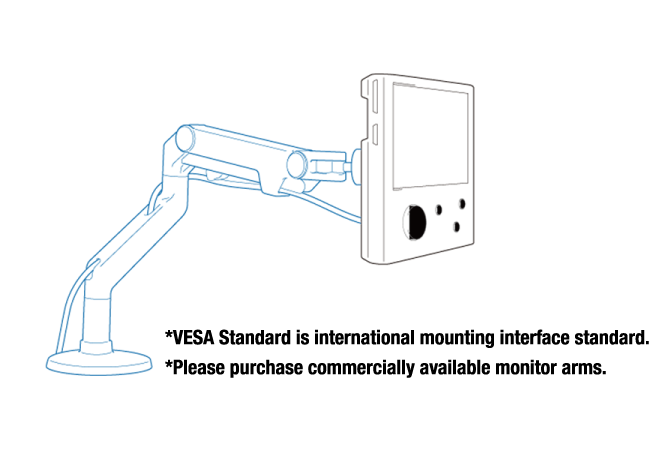

Compliant with VESA Standards (Brother Only)

The LCD touch panel is compliant with VESA standards, enabling to attach to any articulating monitor arm.