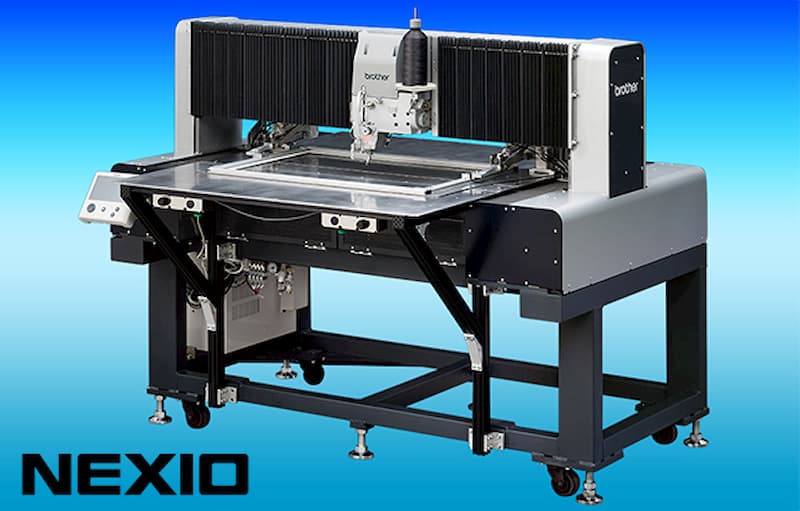

Product

Home > Product > BROTHER > Programmable Electronic Pattern

Description

・Bridge type mechanism provides great sewing quality at higher sewing speeds

| Bridge type mechanism has a feed mechanism of X and Y that drives independently so that it provides great sewing quality at higher sewing speeds(Max. 2,700sti/min). |  |

| Various sizes of sewing threads can be used by the new digital tension which increases the setting range of the upper thread tension. Detects kind of needle thread breakage opportunity immediately, and which reduces defective workpieces. |  |

| It keeps accuracy of stitch point and attains both of high sewing quality and productivity even at high speed sewing. |

| 7-inch large screen and easy programming functions via LCD touch panel enable an intuitive easy-to-use experience. |  |

World’s top-class productivity and sewing quality

Bridge type mechanism has a feed mechanism of X and Y that drives independently so that it provides great sewing quality at higher sewing speeds. A needle cooler preventing thread breakage thus for greater sewing speeds(Max. 2,700sti/min).Effective utilization of factory floor space with compact footprint

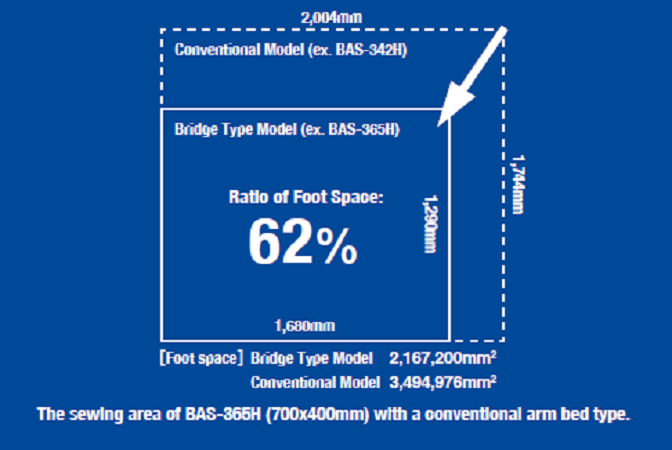

The workspace footprint is extremely small for the larger sewing area provided when compared to conventional type BAS machines *1,allows making additional space for another machine.

*1 Programmable electronic sewing machine with sewing area larger than or equal to 200,000mm2 (BAS-365H: 280,000mm2)

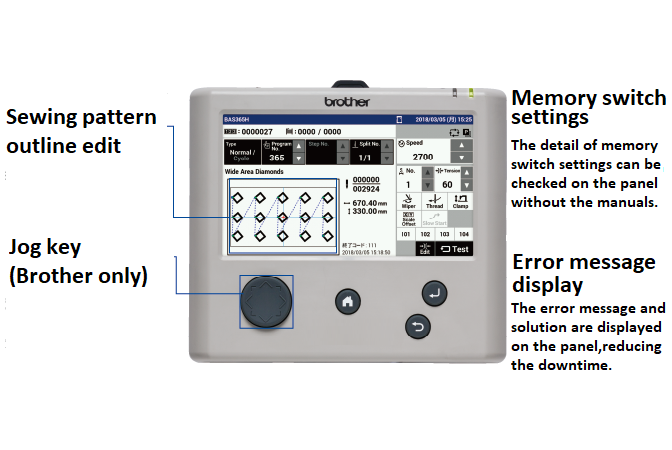

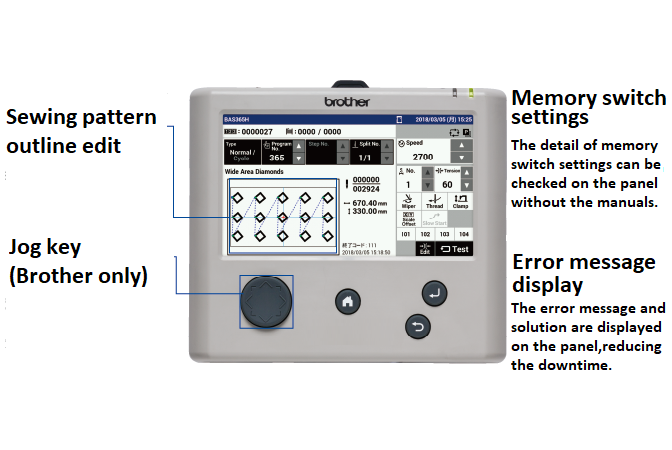

User-friendly color LCD with touch panel display

7-inch large screen and easy programming functions via LCD touch panel enable an intuitive easy-to-use experience.

Productivity improvement by IoT

Brother NEXIO series are IoT applicable models*2.Connecting sewing machine to a network enables customers to analyze, manage processes, improve productivity, and monitor required maintenance.

*2 It is applicable for Brother’s IoT system. For more details, please refer to the catalog of “Brother Industrial Sewing Machine Network System”.

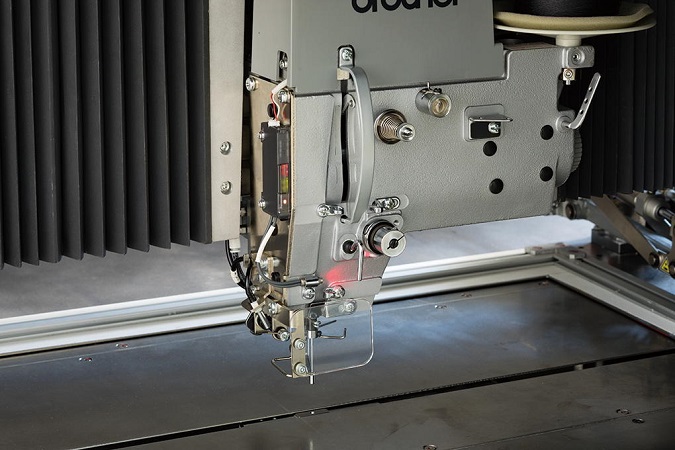

New digital tension allows for a wide variety of threads

Various sizes of sewing threads can be used by the new digital tension which increases the setting range of the upper thread tension.Standard equipment

Needle thread breakage detection mechanism

Detects kind of needle thread breakage opportunity immediately, and which reduces defective workpieces.

Bobbin winder

Bobbin winder is equipped separately. You can place it anywhere the best suited for the machine operation and to use.

Auto eject equipment

It automatically starts sewing after inserting cassette correctly and reduces needle breakages, quality problem, and cycle time.