T-8452C

Twin Needle Direct Drive Split Needle Bar Lock Stitcher with Thread Trimmer

Description

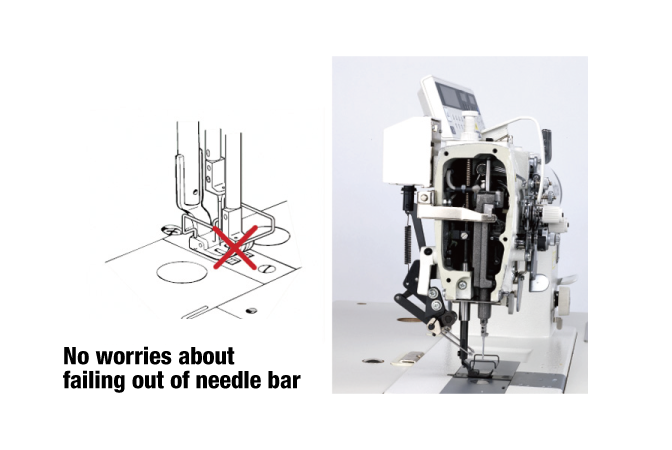

| If you accidentally touch the stop lever (selection lever) duringhigh speed sewing, you do not have to worry. The sewing machine is equipped with the safety mechanism which prevents the needle bar from falling out. Sufficient consideration for safety of sewing operation is given so that fatal damage to the sewing machine will be avoided.(Patent pending) |  |

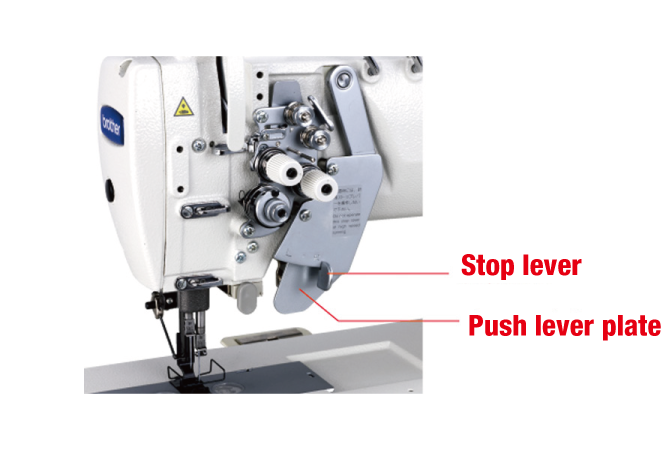

| One of the needle bars can be stopped simply by changing the position of the stop lever (select lever). Compared to the previous models, a stroke of the stop lever has been shortened to optimum stroke and the weight of the lever has also been reduced by about 10 % so that easy operation is possible with a light touch of the lever. The setting can be returned to twin needle sewing simply by pushing the push lever plate. The push lever plate can be removed from the front face of the sewing machine and easily replaced so that it can be adjusted to the best position. In addition, with the adoption of center stop mechanism, the stop lever automatically and accurately returns to the center position to prevent setting errors when it is set back to the twin needle sewing. |  |

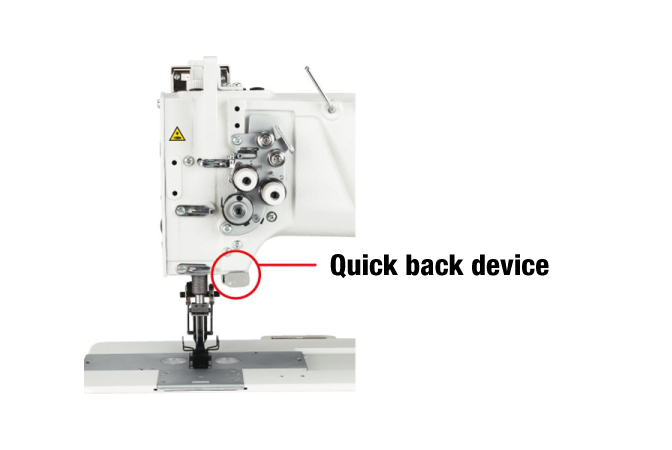

| This is located in a place where it can be pressed easily in order to increase working efficiency. |  |

| Powerful 550W motor outputs large amounts of torque even at slow speeds so that strong needle penetration force can be obtained. This allows accurate sewing of heavy materials and joints. If the needle penetration resistance increases, such as when sewing heavy materials and materials with joints, vibration control (intermittent impact) automatically increases the penetration force.(Patent pending) |  |

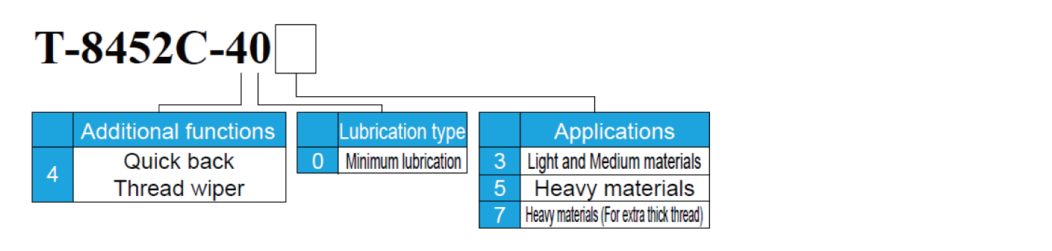

| T-8452C | -403 | -405 | -407 |

| Lubrication type | Minimum lubrication | ||

| Application | Light materials Medium materials |

Heavy materials | |

| Max. sewing speed | 3,000 sti/min | ||

| Needle | DPx5 (#14) |

DPx5 (#22) |

|

| Max. stitch length | 5.0mm | ||

| Presser foot height | 7.0mm | ||

| Start backtacking and continuous backtacking speed | 250〜1,800sti/min | ||

| End backtacking speed | 1,000sti/min | ||

| Height of feed dog | 1.0mm | ||

| Weight | Machine head : 50.0kg Control box : 3.1kg |

||

| Arm pocket size | 120.0 mm x 264.0mm | ||

| Arm bed size | 517.5mm x 178.0mm | ||

| Bobbin winder | Included in machine arm | ||

| Machine head drive | Direct drive mechanism | ||

| Motor | AC servo motor (4-pole,550W) |

||

| Control circuit | Microprocessor | ||

| Power | Single-phase : 100V 3-phase : 200V 400VA |

||