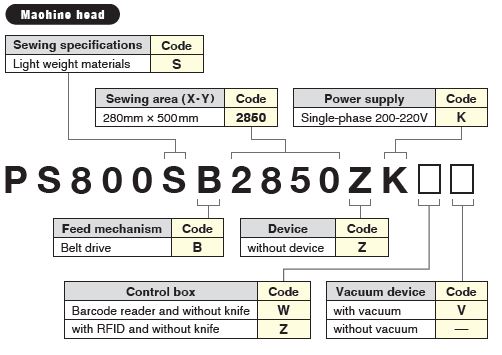

PS-800SB-2850

Pattern Seamer Sewing area 280mm(X) ×500mm(Y)

Description

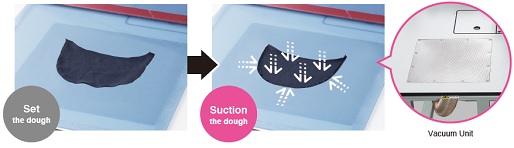

| Easy to set the sewing materials since Vacuum device work under the table. It is help to set softy/light fabric. |

|

| Sewing patterns are automatically identified by means of RFID/ Barcode reader to automatically call up the relevant sewing program, thereby starting sewing quickly. RFID (radio frequency identification) It is the technology to read and write data saved on IC chips through wireless non-contact transfer of radio frequency waves and is used to identify and manage products. |

|

| The sewing pattern data format are supports DXF, AI, PLT, and DST. Sewing pattern data in these formats are widely used in many sewing plants. As a result, the operation panel is able to use the customers' existing sewing pattern data immediately. As many as 999 sewing patterns can be saved on the large-capacity memory of the operation panel. (Editing software is included with the accessory.) |

|

| Model name | PS-800SB-2850ZKZV | PS-800SB-2850ZKZ |

| Sewing area | 280mm × 500mm | |

| Max. sewing speed | 3,500 sti/min* | |

| Lubrication | Semi-dry | |

| Fabric Vacuum Function |

Standard | No (OP device can be retrofitted) |

| Hook | Full-rotary standard-capacity hook | |

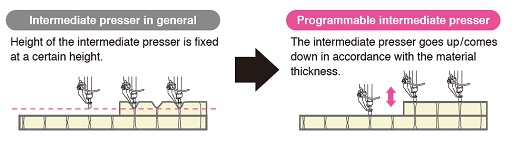

| Lift / Stroke of intermediate presser |

Lifting amount: 9 mm / Stroke: Standard 4 mm | |

| Thread trimmer | Double blades drive rotary knife type thread trimmer | |

| Template recogniser | RFID: 2850DKZ Barcode: 2850DKW |

RFID: 2850ZKZ Barcode: 2850ZKW |

| JaNets device | Retrofittable | |

| Dimensions | 1,060mm (W) × 1,330mm (L) × 1,250mm (H) | |

|

||

| It is possible to change the intermediate presser height at its lower dead point steplessly during sewing. This feature is particularly effective when sewing multi-layered portions of material. Since the material is stably held by the intermediate presser, sewing troubles such as stitch skipping and thread breakage are prevented. |

|

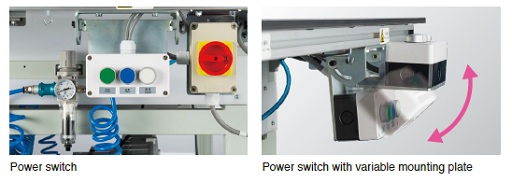

| The power switch operates up and down, so the operator It can be adjusted to a position where it is easy to work. Reduces operator fatigue when sewing for long periods of time. |

|