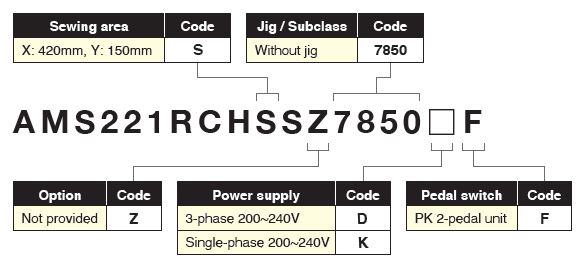

AMS-221RC Series

Computer-controlled Cycle Machine with Input Function (Arc-Motion Cylinder Type)

Description

| The cylinder size is Φ144.5 mm. The largest XY travel range is; X: 420mm and Y: 150mm. With this sewing area, the sewing machine is able to respond to the sewing of large sewing materials. The sewing machine is provided with a cover for the cylinder bed for easy maintenance (JUKI’s original dust-resistant design). |

| Sewing of various kind of desired patterns can be achieved and repeated any time by creating and registering them to the sewing machine memory. With the maximum memory capacity of 500,000 stitches, as many as 999 patterns can be registered. By adopting the large-sized liquid crystal touch panel (IP-420), excellent operability that is common to the AMS Series helps reduce the operator's fatigue when changing set values, inputting/correcting patterns, etc. |

| Model name | AMS-221RC |

| Max. sewing speed | 2,300sti/min* |

| Sewing area | 420mm (X) × 150mm (Y) |

| Stitch length | 0.1~12.7mm (0.05mm step) |

| Needle bar stroke | 41.2mm |

| Intermediate presser lifting | 20.0mm |

| Needle thread tension | Active tension |

| Needle thread breakage detecting device | Equipped as standard |

| Thread falling prevention | Needle thread clamping device |

| Needle | DP×17 |

| Thread | #30~#8 |

| Hook | Rotary double capacity hook |

| Sewing machine motor | Compact AC servomotor (direct-drive system) |

| Thread trimming mechanism | Horizontal knife & individual motor drive |

|

|

| The highly rigid feed mechanism that comes with the LM guide and bearings and the optimized position control produce seams of beautiful shape and stable seam quality. |

| The horizontal knife system that is highly evaluated in the AMS Series is adopted to ensure reliable thread trimming without being affected by the type of thread and the shape of the sewing pattern. In addition, the frequency of bobbin thread changing can be reduced by the adoption of a full-rotary double-capacity hook. |

| The needle thread clamp and needle thread drawing mechanism prevent the sewing trouble, so-called the bird’s nest, at the beginning of sewing. Production capacity can be increased by reducing the thread end securing work. |

|